When it comes to laser engraving machines, two main types dominate the market: fiber lasers and CO2 lasers. Understanding the differences between these two technologies is crucial for making an informed decision about which laser engraver is best suited for your needs. In this article, we will compare the pros and cons of fiber and CO2 laser engravers, so you can choose the right one for your projects.

Key Takeaways:

- Fiber lasers are efficient, stable, and low maintenance, making them ideal for cutting metal.

- CO2 lasers are versatile and can work with a wide range of materials.

- Fiber lasers offer lower operating costs and faster processing speeds.

- CO2 lasers provide better edge quality on plate stainless steel and aluminum.

- Your choice between fiber and CO2 lasers depends on factors such as operating costs, maintenance requirements, and the type of materials you will be working with.

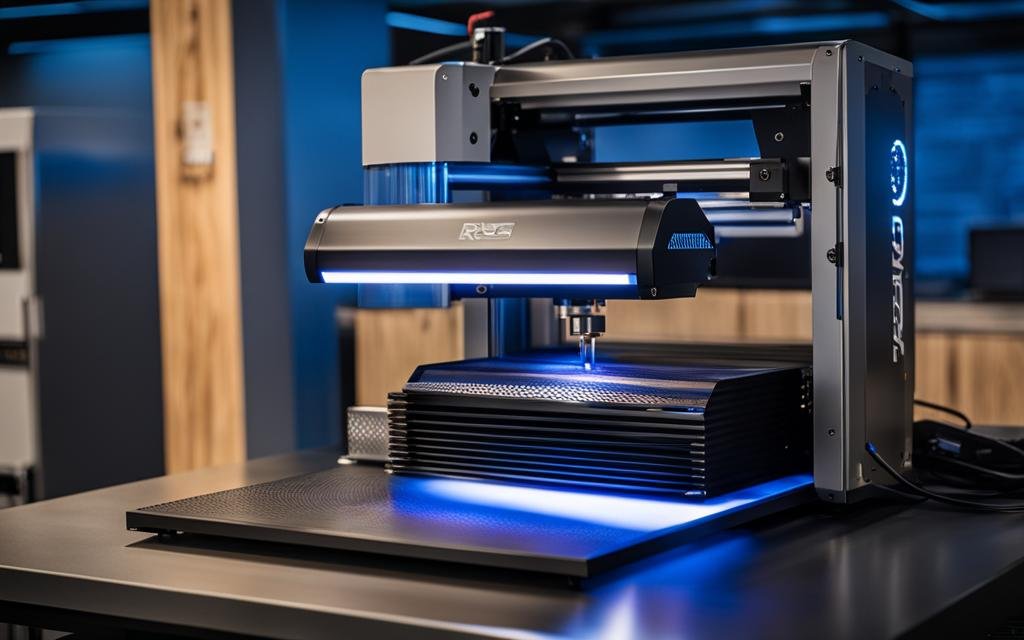

What is a Fiber Laser?

A fiber laser is a type of laser engraver that utilizes fiber optic technology to deliver a powerful and concentrated beam of light to the cutting head. This innovative method simplifies the construction of the laser and results in more affordable fiber laser machines. Fiber lasers are particularly well-suited for creating high-contrast markings on metal surfaces through processes such as annealing, etching, and engraving.

One of the key advantages of fiber lasers is their small focal diameter, which makes them ideal for precision tasks like permanent marking of serial numbers, barcodes, and data matrices. Additionally, fiber lasers offer numerous benefits such as maintenance-free operation and a long service life, making them a reliable choice for businesses in need of consistent and efficient laser engraving technology.

The Benefits of Fiber Lasers:

- Efficient and cost-effective

- Perfect for cutting metals

- High-contrast markings on metal surfaces

- Maintenance-free and long service life

What is a CO2 Laser?

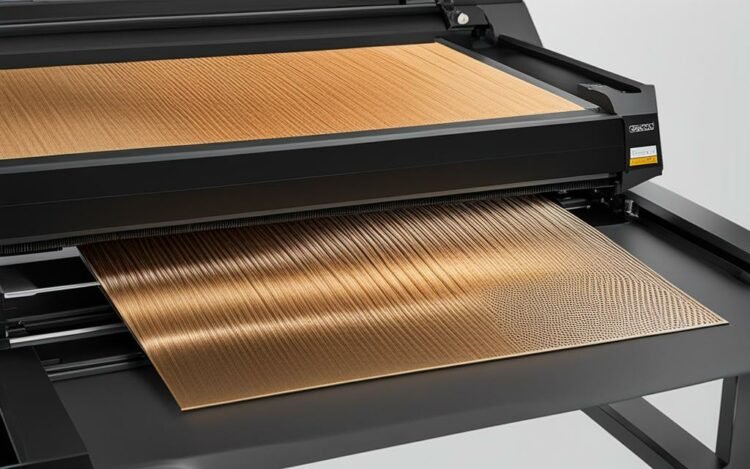

A CO2 laser is another type of laser engraver that utilizes carbon dioxide gases to generate the laser beam. This method allows CO2 lasers to work with a wide variety of materials, including plastics, textiles, glass, acrylic, and wood. They are commonly used in industries such as packaging, where they are employed for marking PVC pipes and electronic components.

CO2 lasers offer faster initial piercing times and produce smoother surface finishes when cutting thicker materials. However, it’s important to note that CO2 lasers have higher operating costs, require more maintenance, and consume more power compared to fiber lasers. Despite these drawbacks, CO2 lasers are highly versatile and widely used in various applications that require the engraving and marking of non-metallic materials.

The Benefits of CO2 Lasers:

- Versatile and can work with a wide range of materials

- Better edge quality on plate stainless steel and aluminum

- Widely used for marking and engraving non-metallic materials

Pro Tip: Get the best deals on laser engravers with exclusive xTool promo codes.

What is a CO2 Laser?

A CO2 laser refers to a type of laser engraving technology that uses a resonator purged with CO2 gases to generate the laser itself. These lasers are commonly used for marking non-metallic materials such as plastics, textiles, glass, acrylic, and wood. With their versatility, CO2 lasers are widely employed in various industries for applications like packaging, marking PVC pipes, and engraving electronic components.

One of the key advantages of CO2 lasers is their ability to offer faster initial piercing times and smoother surface finishes when cutting thicker materials. This makes them particularly suitable for tasks that require precise and clean cuts. However, it’s important to note that CO2 lasers tend to consume more power and require more maintenance compared to fiber lasers.

In summary, CO2 lasers present a valuable option for those looking to work with non-metallic materials and achieve high-quality cuts. While they may consume more power and require more maintenance, their versatility and superior cutting performance make them a popular choice.

Pros and Cons of Fiber Lasers

Fiber lasers offer a range of benefits that make them a popular choice in the laser engraving industry. Here are some key advantages:

- Lower operating costs: Fiber lasers are highly efficient and consume less power compared to CO2 lasers. This results in significant cost savings, especially for cutting applications.

- Faster processing speeds: Due to their high power density, fiber lasers can achieve faster cutting and engraving speeds compared to CO2 lasers. This allows for increased productivity and shorter production times.

- Higher precision: Fiber lasers provide exceptional accuracy and precision, making them ideal for intricate designs and detailed engraving. They can achieve fine details with crisp edges, ensuring high-quality results.

- Less maintenance: Fiber lasers are known for their reliability and long service life. They require minimal maintenance, resulting in reduced downtime and increased productivity.

However, it’s important to consider some limitations of fiber lasers:

- Non-metal applications: While fiber lasers are excellent for cutting metals, they may have limitations when it comes to certain non-metal materials. Achieving the same level of finish as CO2 lasers in thicker materials can be challenging.

- Specialized applications: Fiber lasers are primarily used for cutting and engraving metals. If your engraving needs involve a wide range of non-metal materials, a CO2 laser might be a more versatile option.

Fiber Laser Applications

Due to their unique advantages, fiber lasers are commonly used in various applications. Some notable examples include:

- Metal cutting and engraving: Fiber lasers are highly effective for cutting and engraving metals, such as stainless steel, aluminum, and brass. They can achieve precise, clean cuts and detailed engravings on these materials.

- Serial number and barcode marking: The small focal diameters of fiber lasers make them suitable for permanent marking of serial numbers, barcodes, and data matrices on metal surfaces.

- Annealing and etching: Fiber lasers are often utilized for high-contrast markings on metal surfaces, such as annealing and etching. These processes create durable, legible marks without affecting the material’s structural integrity.

When considering a laser engraver, understanding the pros and cons of fiber lasers can help you make an informed decision. Evaluate your specific needs, materials, and budget to determine if a fiber laser is the right choice for your laser engraving projects.

Pros and Cons of CO2 Lasers

CO2 lasers have gained popularity in the laser engraving industry due to their versatility and ability to work with a wide range of materials. However, like any technology, CO2 lasers have their pros and cons that you should consider before investing in a laser engraver.

Benefits of CO2 Lasers

- Wide Range of Applications: CO2 lasers are suitable for engraving and marking various non-metallic materials, including plastics, textiles, glass, acrylic, and wood. This versatility allows you to explore different creative possibilities.

- Better Edge Quality: When it comes to cutting plate stainless steel and aluminum, CO2 lasers offer superior edge quality. This makes them ideal for projects that require clean and precise finishes.

Considerations for CO2 Lasers

- Higher Operating Costs: CO2 lasers consume more power compared to fiber lasers, resulting in higher operating costs. It’s important to factor in the potential increase in electricity bills when choosing a CO2 laser engraver.

- Increased Maintenance: CO2 lasers require more maintenance compared to fiber lasers. Regular cleaning and alignment adjustments are necessary to ensure optimal performance and prolong the lifespan of the machine.

When considering a CO2 laser engraver, take into account the specific benefits and considerations outlined above. Evaluate your needs, materials, and budget to determine if a CO2 laser is the right choice for your laser engraving requirements.

Conclusion

When it comes to choosing between a fiber laser and a CO2 laser engraver, it’s essential to consider your specific needs and applications. Fiber lasers are a great choice if you primarily work with metals. They offer high efficiency, low maintenance, and cost savings in the long run. On the other hand, CO2 lasers are more versatile and can handle a wide range of materials, including non-metals.

Factors such as operating costs, maintenance requirements, and power consumption should be taken into account. If you’re in the laser engraving industry, understanding the pros and cons of each type of laser engraver is crucial for making an informed decision. By comparing fiber lasers and CO2 lasers, you can determine which technology suits your laser engraving needs best.

Ultimately, whether you choose a fiber laser or a CO2 laser engraver depends on the type of materials you work with and your priorities. Both options have their advantages and disadvantages. Consider the specific demands of your projects and the capabilities of each laser engraver. With the right knowledge and understanding of the laser engraving industry, you can make a confident decision and enhance your laser engraving business.