When it comes to laser engraving, choosing the right materials is key to achieving the desired results. Whether you’re looking to create intricate designs on wood, add elegance to glass, personalize metal, or work with versatile acrylic, understanding the options and compatibility of laser engraving materials is essential.

Wood, acrylic, glass, and metal are among the most popular materials used for laser engraving. Each material has its own unique characteristics and considerations, and selecting the right one depends on your specific project requirements and desired outcomes.

In this article, we will explore the different laser engraving materials, their compatibility with laser machines, and the specific settings required for each material. By understanding the options available and considering the factors that impact the engraving process, you can ensure successful and high-quality results.

Key Takeaways:

- Choosing the right materials is crucial for successful laser engraving projects.

- Wood, acrylic, glass, and metal are popular options for laser engraving.

- Consider the compatibility of materials with laser engraving machines.

- Adjust the settings based on the specific requirements of each material.

- Factors like density, color, and thickness can affect the engraving quality.

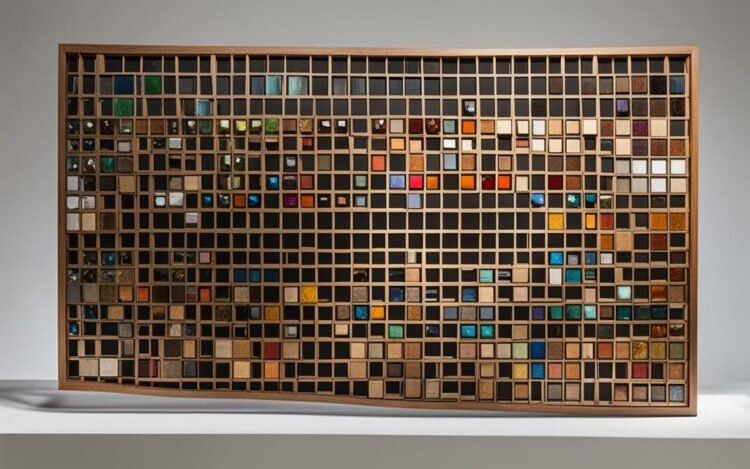

Wood: A Natural and Versatile Option for Laser Engraving

Wood is a highly sought-after material for laser engraving due to its natural beauty and versatility. When it comes to laser cutting and engraving wood, there are various factors to consider to achieve the best results.

Types of Wood for Laser Engraving

There are different types of wood that are commonly used for laser engraving. Hardwoods like maple, cherry, and walnut are ideal for detailed engravings due to their tight and uniform grain. They provide excellent precision and lend a high-end and polished look to the engraved designs. On the other hand, softwoods like pine and cedar can be used for a more rustic or vintage appearance, but they may result in less precision due to their looser and less uniform grain.

Choosing the Right Wood

When selecting wood for laser engraving, it’s important to consider the specific requirements of your project and the desired engraving effect. Consider the thickness and orientation of the wood grain, as they can impact the quality and depth of the engraving. Additionally, if you’re looking for cost-effective alternatives, plywood is a great option. It offers the benefits of traditional woods but at a more affordable price point, making it an excellent choice for projects with budget constraints.

Overall, wood provides a natural and versatile canvas for laser engraving. With the right selection of wood and careful consideration of factors like grain type and thickness, you can achieve stunning results and create personalized and unique pieces.

Pro Tip: Need a laser engraver at a discounted price? Explore xTool deals and promotions for great offers.

Acrylic: A Versatile and Durable Material for Laser Engraving

Acrylic is a highly versatile material that is well-suited for laser engraving. Its durability and ability to create intricate designs make it a popular choice among engravers. When it comes to laser cutting acrylic, there are a few factors to consider to ensure optimal results.

Choosing the Right Acrylic for Laser Engraving

When selecting acrylic for laser engraving, it’s important to choose the right type of acrylic. There are two main options: cast acrylic and extruded acrylic. Cast acrylic is preferred over extruded acrylic for its cleaner finish, making it ideal for high-quality engravings.

Best Acrylic for Laser Engraving

Clear or white acrylics are generally the best choice for laser engraving as they allow for maximum visibility of the engraving. However, colored acrylics can also be used with limitations. It’s important to note that colored acrylics may require adjustments to the power and speed settings to achieve the desired engraving depth and clarity.

Acrylic Color for Laser Engraving

When selecting acrylic color for laser engraving, it’s best to choose colors that have a high contrast with the material. This will ensure that the engraved design is easily visible. It’s also worth noting that darker acrylic colors may require higher power settings to achieve the desired engraving depth.

In summary, acrylic is a versatile and durable material that is well-suited for laser engraving. By choosing the right type of acrylic and considering factors such as color and compatibility with laser engraving machines, you can achieve high-quality engravings with acrylic materials.

Glass: Adding Elegance to Laser Engraved Items

Laser engraving on glass can add a touch of elegance to any item, whether it’s a personalized gift or a custom-made decoration. However, engraving on glass requires careful attention and specific techniques to ensure a successful outcome. Here are some tips to help you achieve the best results when laser engraving on glass:

- Choose the right type of glass: Not all types of glass are suitable for laser engraving. Look for glass specifically designed for laser engraving to ensure better results. These types of glass are more resistant to cracking and provide a smoother engraving surface.

- Prevent glass cracking: Glass is a fragile material that can crack or shatter under intense heat. To prevent cracking, use lower power settings and higher engraving speeds. This will help distribute the heat more evenly and minimize the risk of damage.

- Use wet paper towels or masking tape: Placing wet paper towels or applying masking tape to the surface of the glass can help dissipate heat and improve the engraving outcome. This technique helps reduce the risk of overheating and ensures a cleaner engraving.

- Practice on scrap glass: Before engraving on the final project, it’s always a good idea to practice on scrap glass pieces. This allows you to test different settings and techniques without the risk of ruining the actual item.

When it comes to the suitable thickness of glass for laser engraving, it’s important to consider the power of your laser machine. Thicker glass may require more power to achieve a deep engraving, while thinner glass may be more delicate and require lower power settings. Experimentation and practice will help you determine the optimal settings for different types and thicknesses of glass.

Remember, laser engraving on glass requires precision and attention to detail. By following these tips, you can create stunning and elegant laser engraved glass items that truly stand out.

Metal: Durability and Personalization in Laser Engraving

Metal is a highly sought-after material for laser engraving due to its durability and the ability to create personalized designs. When it comes to laser cutting on metal, there are several important factors to consider in order to achieve the best results.

Choosing the right laser for metal engraving

- When selecting a laser for metal engraving, it is important to choose one with sufficient power to effectively engrave the metal surface. Fiber lasers or CO2 lasers with specialized marking compound are commonly used for metal engraving.

Power and speed settings for metal engraving

- The power and speed settings for metal engraving depend on the type of metal and the desired engraving depth. Different metals require different power settings, and delicate metals like gold and silver require extra care.

Cleaning metal before engraving

- Thoroughly cleaning the metal surface is crucial for achieving a clear and precise engraving. Any dirt, dust, or oils on the metal can interfere with the engraving process and affect the quality of the final result.

Suitable metals for laser engraving

- Not all metals are suitable for laser engraving. Some metals, like stainless steel and aluminum, can be engraved with excellent results, while others, like copper and brass, may require specialized processes and equipment.

When it comes to laser engraving, metal offers durability and endless possibilities for personalization. By considering factors such as the right laser, power and speed settings, cleaning procedures, and suitable metals, you can achieve stunning results in your metal engraving projects.

Factors to Consider When Choosing Laser Engraving Materials

When it comes to laser engraving, selecting the right materials is crucial for achieving the desired results. Several factors should be taken into consideration in order to make the best decision for your project. Here are some key factors to consider when choosing laser engraving materials:

- Material Compatibility: Not all materials are compatible with laser engraving machines. It is important to ensure that the material you choose can withstand the heat and intensity of the laser without warping, melting, or producing harmful fumes.

- Laser Engraving Material Properties: Each material has its own unique properties that can affect the quality and appearance of the engraving. Consider factors such as density, color, and thickness to determine if the material is suitable for your specific project.

- Desired Engraving Effect: Think about the desired outcome of your engraving. Different materials can produce different effects, such as a rustic look on wood or a sleek and polished finish on metal. Choose a material that aligns with your aesthetic goals.

Additionally, it is important to consider the specific requirements of your project. Factors such as size, shape, and intended use of the engraved item can impact material selection. By carefully considering these factors, you can choose the right materials that will result in high-quality, personalized laser engravings.

Choosing the Right Material for Laser Engraving Projects

When it comes to laser engraving projects, choosing the right material is essential for achieving the desired outcome. Here are some additional factors to consider when selecting materials:

- Durability: Consider the durability of the material to ensure that it can withstand regular use without fading or deteriorating over time.

- Ease of Engraving: Some materials are easier to engrave than others. Consider the intricacy of your design and choose a material that will allow for precise and detailed engravings.

- Availability: Ensure that the chosen material is readily available and accessible, especially if you require a large quantity or have a tight deadline for your project.

By taking all of these factors into account, you can make an informed decision when choosing laser engraving materials. Remember to test different materials and settings before starting your project to ensure optimal results.

Conclusion

When it comes to laser engraving materials, choosing the right ones is crucial for achieving the best results. Wood, acrylic, glass, and metal are all popular options, each offering unique characteristics and considerations.

Consider factors such as material compatibility with your laser engraving machine and the specific settings required for each material. Pay attention to the properties of the material, such as density, color, and thickness, as these can impact the quality of the engraving.

Additionally, think about the desired engraving effect and the specific requirements of your project. By carefully considering these factors, you can choose the best laser engraving materials for your needs.

Remember, the right materials will ensure that your laser engraving projects are successful and produce high-quality, personalized results. So take the time to select the materials that will bring your vision to life.